South Eastern Railway – GRP Walkway – Victoria Light Maintenance Depot

On average, 1.7 billion people use the British railway each year. Consequently, the network relies on thousands of engineered components. Many are unseen structural elements that act like cogs behind the railway’s clockface. As a result, our GRP walkway and platform system keeps those cogs aligned and Britain moving safely.

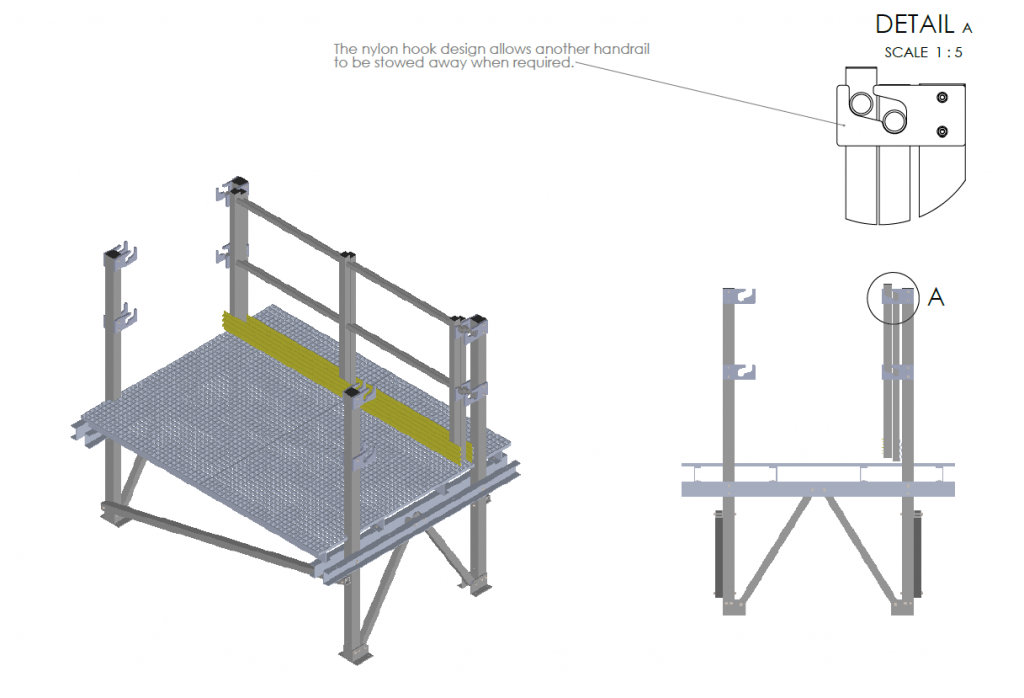

Precision Engineering at Victoria Depot

Jasper Products designed, fabricated, and installed a 560m GRP walkway at Southeastern Railway’s Victoria depot. Therefore, the project demonstrates precision rail engineering. Simple decisions, such as platform height and width, soon became complex challenges. However, detailed planning, accurate surveying, and careful calculation resolved each issue.

Engineering for Height Consistency

A topographical survey revealed major ground‑level variation along the depot. Consequently, the team engineered every walkway section to precise, location‑specific dimensions. This ensured a consistent platform height beside the train carriages.

Designing for Multiple Train Types

Width required equal attention. Additionally, many train models and carriage types may dock at the station. Therefore, the walkway could not exceed the largest carriage profile. Each train moves within a dynamic envelope that shifts on straights and curves. The walkway therefore needed to allow maximum overthrow while keeping operatives safe. Meanwhile, the team minimised the gap between train and walkway to reduce risk.

Meeting Safety Standards

The team calculated height and width in strict accordance with Railway Group Standards. Furthermore, these standards ensured full operational compliance.

Why GRP Was the Right Choice

Mathematics was not the only priority. Instead, the design also needed durability, low maintenance, and a safe working environment. GRP provides all three benefits in modern rail infrastructure. Its corrosion resistance and long service life offer clear advantages over traditional materials.

The team therefore chose to fabricate the walkway and platform almost entirely from GRP. As a result, the depot gained a safer and more efficient working platform that will perform for decades.

Keeping maintenance operatives safe and providing them with uncomplicated, intuitive access to perform their necessary work is an important step in the process of maintaining the rail network. It is thanks to careful background jobs like these across the country that keep the trains moving, and people all over Britain connected.

See more of our bespoke work platforms here Innovative Ideas