South Eastern Railway – GRP Walkway – Victoria Light Maintenance Depot

On average, 1.7 billion people use the British railway every year. It is a large, nation spanning network, made up of thousands of moving parts and components. A great majority of these are unassuming background elements, hidden from public view, that fit together as the cogs behind the clockface of the public railway. Each cog must be perfectly matched if we are to keep Britain moving.

The 500m+ walkway that Jasper Products designed, fabricated, and installed at South Eastern Railways Victoria maintenance depot is an example of that precision background engineering. What might seem like simple decisions, such as determining the correct height and width of the platforms, were made circumstantially complicated. Yet, this was nothing that could not be overcome with thorough planning and calculation.

Though the height of the platform would have to be level and consistent alongside the carriages, a topographical survey returned a high range of deviation in ground levels along the length of the walkway. If the walkway was to be even, the heights of each segment of the platform would have to be tailored exactingly to their intended location.

Similarly, the ideal width of the walkway had to be carefully calculated. With multiple train models and carriage types liable to dock in the station, the walkway could not be any wider than the largest carriage. Furthermore, each train possesses a range of possible dynamic motion while moving along the tracks. The elbow room each train requires varies more so at different points along the track, changing on straights and corners. Therefore, the walkway could not be any wider than the largest overthrow of any carriage, nor could it be too narrow, both to allow operatives to manoeuvre equipment past each other, and to minimize the safety risk posed by too large a gap between the train and walkway.

Both of these factors were carefully evaluated with regards to the Railway Group standards in order to create the ideal dimensions for the walkway.

But exacting mathematics wasn’t the only priority when it came to the design of this project. Better than fitting into the designated space, Jasper Products saw the opportunity to elevate the project through innovative choices, to the benefit of the maintenance depot.

The decision was made to fabricate the walkway almost entirely out of GRP (glass reinforced plastic, or fiberglass). GRP is non-conductive, which made it the ideal choice to protect the workers from the live third-rail that the walkway was commissioned to cover. The project also benefited from the other advantages of GRP, including it’s high strength to weight ratio, and its resistance to corrosion, abrasive chemicals, and weathering.

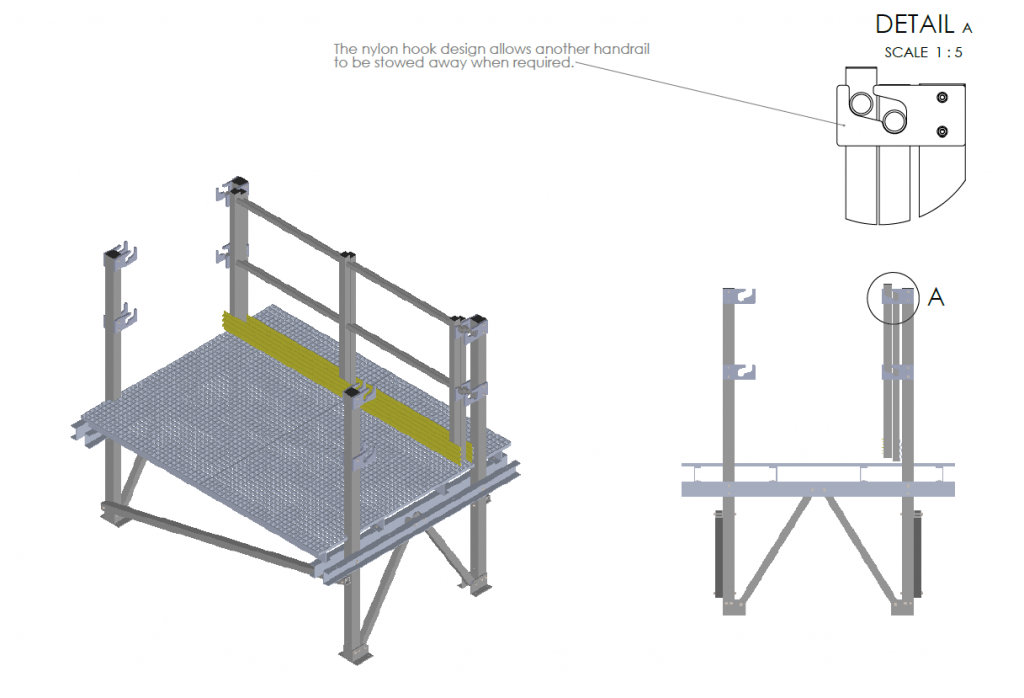

Similarly, handrails on a walkway are a necessary component of keeping staff safe while traversing alongside the carriages. Nevertheless, they were taken as a chance to invent. Jasper Products unique design makes each individual segment of the handrails removable in order to allow maintenance workers access to any point along the train easily, without the need for tools. Moreover, the design of the handrails allows for any removed section of rail to be safely slotted into and stored against any other, keeping the walkway clear. Operatives can easily put a section aside while they work and then replace it just as simply, without compromising the safety of others using the walkway.

Keeping maintenance operatives safe and providing them with uncomplicated, intuitive access to perform their necessary work is an important step in the process of maintaining the rail network. It’s thanks to careful background jobs like these across the country that keep the trains moving, and people all over Britain connected.