BP Gas Filter Platforms:

Necessarily, bespoke access solutions come in all shapes and sizes. This is never more true than when it comes to providing access to restricted and confined spaces. For these kinds of projects, it is critical to identify complications in advance, and to actively work to solve them before they are allowed to occur.

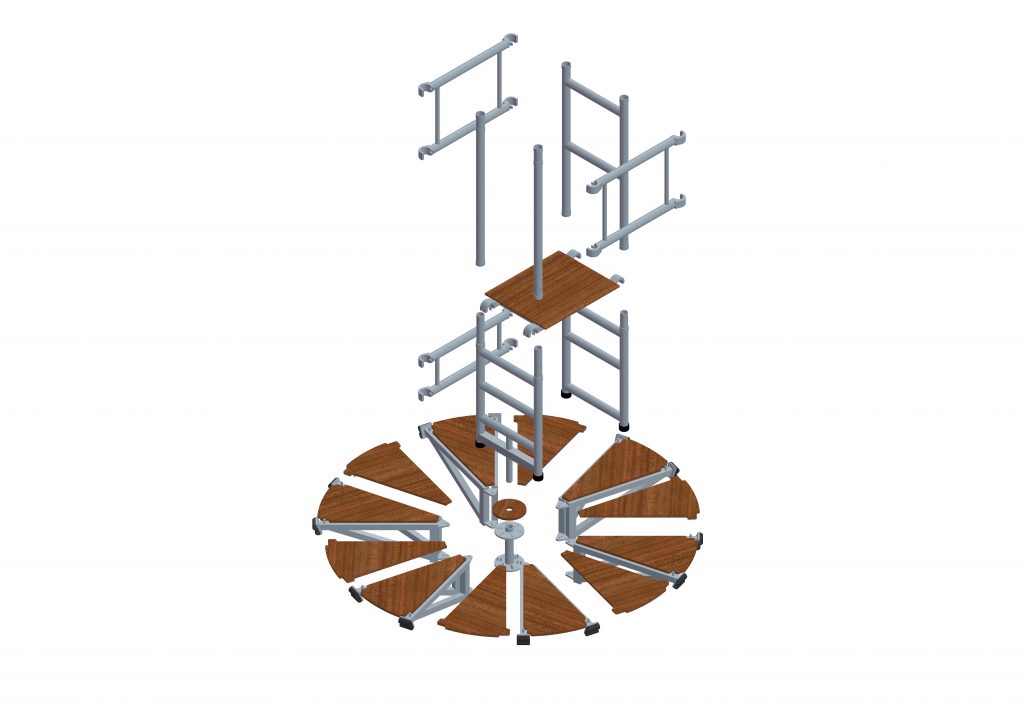

BP’s TAR team were tasked with improving the efficiency and safety at which maintenance duties were carried out on a vessel located offshore in Angola. In addition to being located on an offshore confined space, the brief had other specifications which could have made the job a challenge. Components couldn’t be over a certain size, due to limited diameter restricted access into the vessel; installation would need to be fast and efficient due to the critical turnaround period; inertia would have to be considered at the calculation stage; fixing capabilities from within the vessel would be limited. Facing this multifaceted task, they contacted Jasper Products to help.

To account for the restricted size and to identify any obstacles that we might face antecedently, our team created a mock-up of the vessel in our workshop. Using this framework to test tolerances, we recognised an issue that might arise once the platforms were in place, given the limited fixing capabilities within the vessel.

Our solution was to implement a friction fit system. More mock-ups and in-house coefficient tests followed by physical load testing, recording movements and reactions, helped us isolate and find the answers to future issues that our client might have.

Once the final trials and quality checks were completed the components were boxed and labelled in their respective cases.